About Royal Robotics

Our mission is to design, build and program robots that solve real-world challenges while creating a love for STEM in our community. We aim to push boundaries of technology and inspire the next generation of problem solvers and engineers!

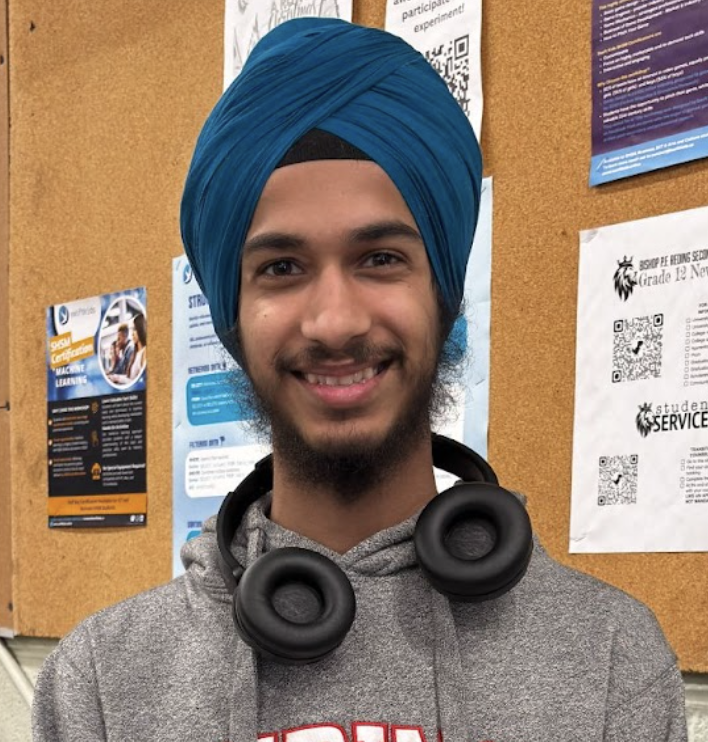

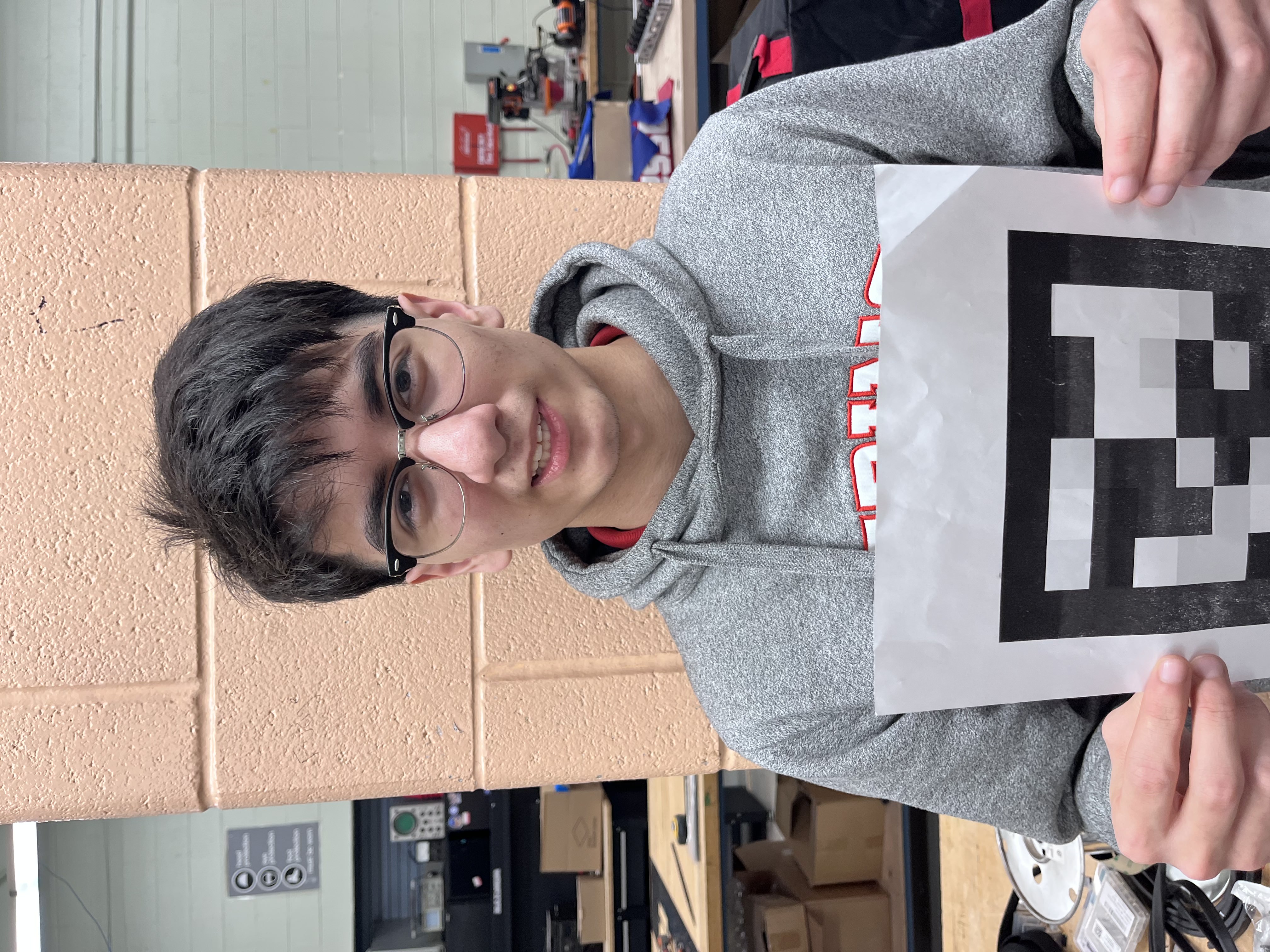

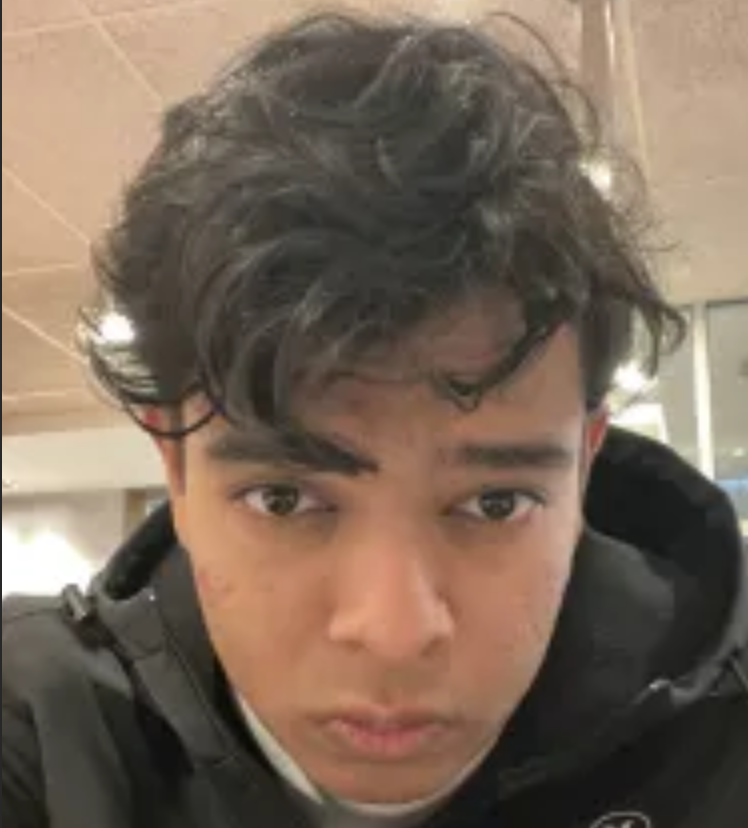

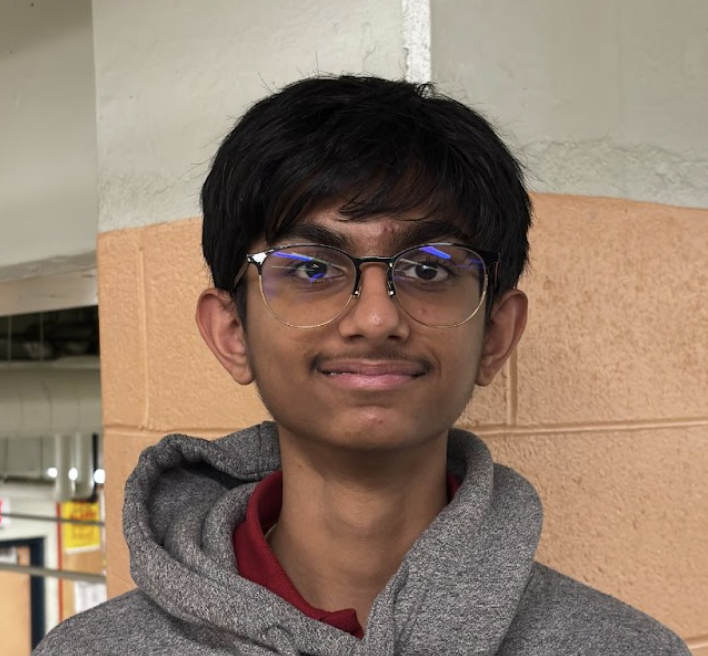

Meet Our Team

Our dedicated team members work tirelessly to design, build, and program our competition robots while promoting STEM education and teamwork.

We're Recruiting New Members!

Want to be part of the Royal Robotics Team? If yes, you are in the right place! Join us and develop skills in engineering, programming, design, and teamwork.

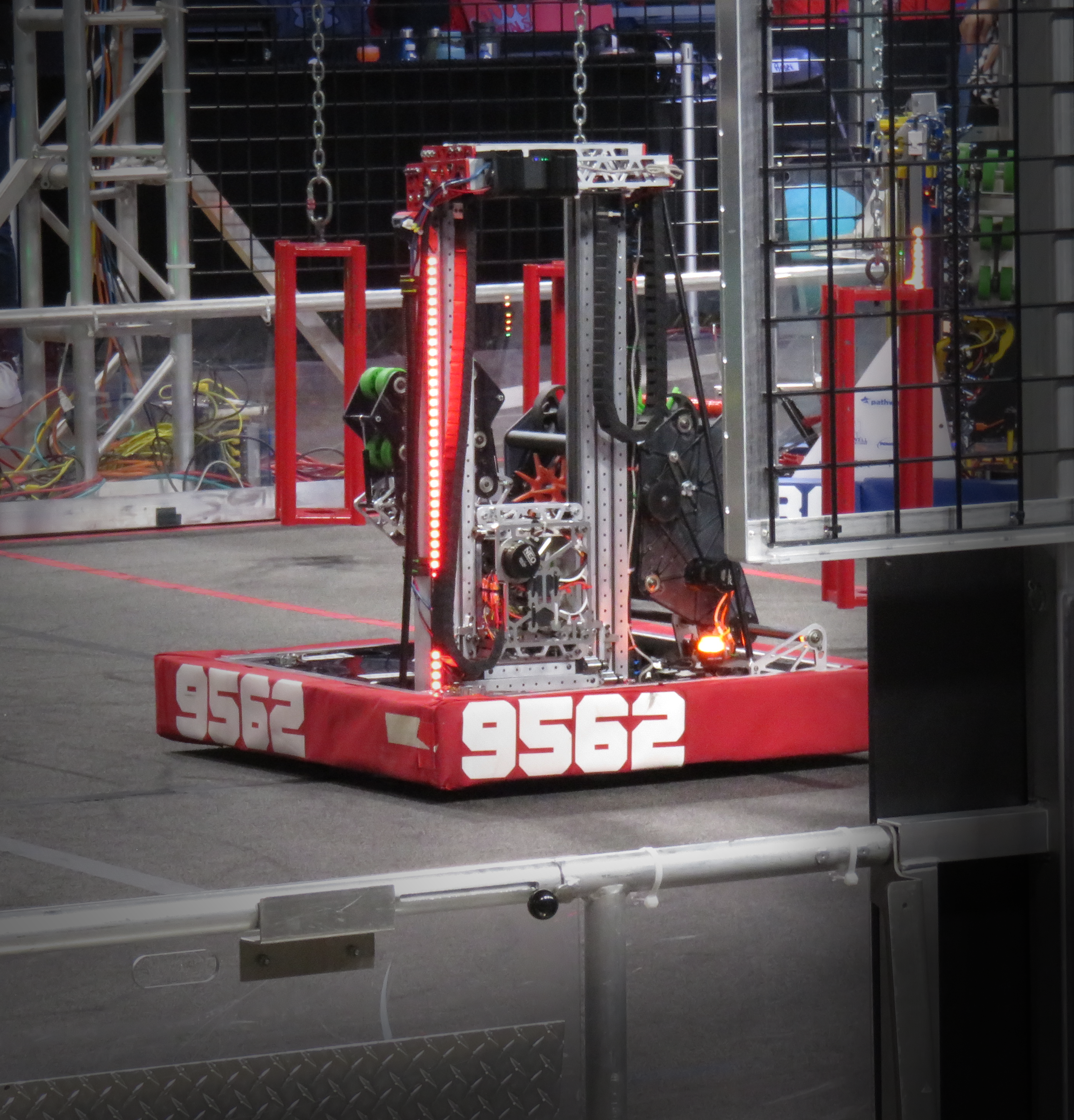

Robot Components

Discover the key features of our competition robot

Fabrication

In our workspace we heavily used our 2 X-carve CNC to cut .090" thick 6061 aluminum, and ⅜" poly carbonate. We also used our sienci long mill mk1 to aid in drilling precise hole in 1"x1", and 2"x1" extrusions. Many of our more geometrically complex parts were sent out to our gracious sponsor "Sable Metal" to be laser cut from 6061 aluminum and we thank them for all the support they have given us!

Drive Terrain

ChassisMK4i Swerve Modules with L2 gear ratios are driven by 2 NEO V1.1 motors, utilizing Spark Max controllers, achieving a maximum speed of 4.9 m/s. YAGSL is employed for the swerve drive software. The chassis measures 32 inches long by 27.5 inches wide. It features 2056 style 3D printed swerve covers. The base plate is made from 0.090" thick laser-cut aluminum parts.

Intake

For our design, we required an under-bumper intake system that would effectively feed the note directly into the shooter. We needed it to be quick, robust, and easy to service, all while being gentle with the note. A NEO V1 motor drives the intake with a 14 to 45 gear reduction ratio. The intake is 2 inches wide and is attached to the front chassis rail using "T-Nut" style slots in the ⅜" polycarbonate plates.

Our Achievements

Our dedicated team members have worked tirelessly to achieve these prestigious awards and to create innovative robot designs. Their commitment, creativity, and teamwork have been the driving force behind our success in competitions.